|

The iCT's pioneering capacitive measurement cell is manufactured in ceramic, a material impervious to chemical attack for most applications. Careful design of the sensor means the diaphragm is fully supported and protected against overload and shock pressure conditions.

Advanced signal processing provides an increased operational span and sensitivity compared with conventional capacitive devices, reducing the number of nominal ranges to 4 to cover all tank depths up to 50 meters WG, all with the same high performance levels.

The iCT transmitter body is manufactured from high integrity 316 stainless steel and employs a carefully engineered seal assembly in a choice of materials, which draws upon PSM's many years of application experience to provide a fully submersible (IP68) construction capable of withstanding the toughest operating conditions.

Advanced features are not confined to mechanical design. The iCT features a powerful onboard micro-controller utilising a unique digital processing principle, to precisely monitor the pressure related output of the capacitive cell. Ambient temperature is also monitored to provide a fully compensated level signal. The level signal can then be further processed by a comprehensive range of functions and outputs, all under the user’s control.

Analogue Mode

In Analogue only mode iCT can be operated as a conventional 4-20 mA, two-wire transmitter with an accuracy of 0.25 per cent, compensated over a temperature range of –10 to +80 deg C.

iCT will dirctly replace PSM’s earlier generation of level transmitters and other conventional instruments.

Even when used as a conventional 4-20mA transmitter, the benefits of digital processing are immediately apparent. The 4 to 20mA signal can be compensated for any tank shape and S.G. so the output is in true volume not just level. With digital control of the output signal, excellent long-term stability and reliability is assured.

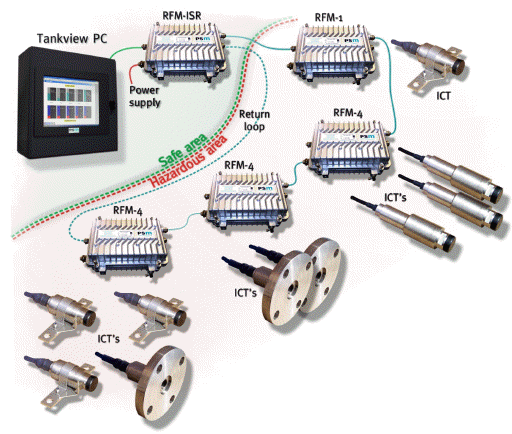

When partnered with PSM’s RFM range of termination modules* installation is greatly simplified, and PSM’s ISS configuration software*, allows setting of instrument calibration without the need to apply test pressures.

Digital mode

In digital mode the real power of the transmitter becomes apparent. iCT can communicate directly with a host PC via an industry standard RS485 multi-drop network using standard Modbus protocol. Using the direct digital output with its full 16 bit measurement precision, accuracy improves to 0.1% under normal conditions.

In digital mode the iCT also provides measurement of process temperature.

Up to 127 transmitters can be multi-dropped over a single 2 wire RS 485 network. Connection to the host PC uses either RS232 or USB standard via a simple low cost converter module available from PSM.

In digital mode the power requirement is just 3mA at 8 to 30V DC. This, combined with a rapid settling time means the iCT is ideal for battery powered applications

The embedded processing power of the iCT means it can be configured for specific tank shapes, S.G.’s, offsets, alarm points, etc, to provide fully scaled digital and analogue outputs. All configuration may be backed up on a PC for download to new / replacement units.

Simple Networking

PSM’s RFM family partner the iCT to simplify multi-drop installation and provide full ATEX Intrinsic Safety compliance. See separate details

Digital communication uses the industry standard Modbus protocol, meaning OEM’s and system integrators, have access to the full range of calibration, diagnostic, and reporting facilities. Alternatively PSM’s own integrated support system (iSS) is a powerful windows based application created specifically to harness the full functionality of the iCT.

Full details of the iSS are provided on a separate leaflet, a summary of functions can be found here

PSM's Tankview provides the simple solution for data collection, control and display

Approvals

The iCT is available with ATEX Intrinsic Safety Approval for use in hazardous areas, and can be specified as 'Type Approved' by all major marine classification societies.

Applications

The construction materials employed, the variety of fittings available, and the wide measurement range mean the iCT is suitable for most tank level applications in the marine, offshore, food, chemical, water, and processing industries. The iCT may also be used for absolute or vacuum measurement applications, if this requirement is specified at time of order.

PSM and our agents will be pleased to discuss your application needs

Digital benefits

-

Remote access. The full functionality of any transmitter in the network can be accessed from any point.

-

Accurate re-ranging and/or zero adjustment simply by entering new values. There is no need to employ external test equipment and pressure generators. The unit does not even have to be removed from service.

-

Accurate temperature measurement. The iCT has an integral temperature sensor to correct its own measurement. In digital mode, the current process temperature may also be output via RS485

-

Monitoring of service conditions and extremes. The unit will record the total hours run and the lowest and highest in service pressures and temperatures it has measured to assist in trouble-shooting.

-

Tank characterisation. The digital output can be linear or corrected for non-linear shaped storage tanks using the programmable look-up table to provide a direct output in volumetric units. This benefit is also available for the analogue output. The 4-20mA signal can be corrected using the same look-up table, allowing simple, low-cost indicators to be used for volumetric display.

-

Error reporting. Internal diagnostics continually monitor the health of the iCT. In the event of errors (for example, the 4-20mA output becoming inaccurate), an appropriate error bit is sent for transmission to the host display.

-

High and low alarms with variable setpoint debounce and hysteresis

-

Rate of change alarms. For the detection of tank leakage.

-

Force zero/span. This fixes analogue output to 4 or 20mA for an actual signal within a defined band of these points. In addition, the analogue output can be forced to a programmable fixed value between 3 and 22.5mA for the indication of faults where the unit is being used conventionally.

-

Analogue output switching. The operator can switch the 4-20mA output to 4, 12, and 20mA via the ISS, irrespective of the actual input pressure, providing a powerful proving and calibration tool for the testing of display equipment.

-

All configuration data is held in a non-volatile memory.

Installation flexibility

The sensor is fully submersible as standard, and a full range of fittings are offered to allow external flanged or threaded mounting, or internal clamped or pole mounting.

The iCT’s processing power is contained within its body, allowing direct connection of its cable to monitoring equipment.

The optionally offered Remote Function Module (RFM) ** family of termination enclosures and Intrinsically Safe barriers, provide simplified multi-drop installations with provision for “looping through” of the RS485 and power cables

|